Net-Zero Manufacturing Facilities: Obstacles and Benefits

The decision to pursue net-zero facility design in manufacturing is complicated. There are significant challenges related to initial project costs, physical space constraints, and project site considerations—but also substantive benefits from operational savings, environmental impact, building brand trust, and working toward a more sustainable future.

Projects can implore creative strategies to navigate challenges, and the people involved in projects can take steps to break free of a traditional project management approach. This approach focuses solely on schedule and costs to adapt a more collaborative process that places environmental impact above other factors. Though net zero is an objective and quantifiable metric, organizations should still strive to adapt as many of these practices as possible into their project delivery model, even if reaching net zero may not be feasible for a given project. With manufacturing in the US continuing to grow at an astounding rate, every project where we can ask the hard questions early and integrate some of these approaches makes critical progress toward a more sustainable future for the manufacturing industry at large.

BACKGROUND

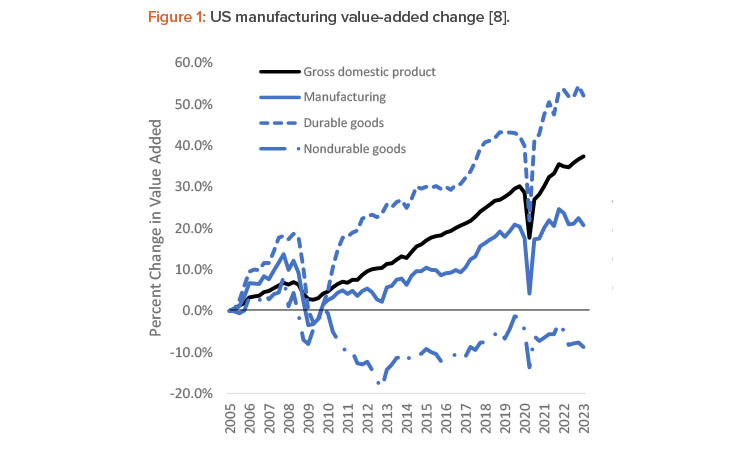

The current social and industrial landscape is dominated by trends that inform organizational policies and strategic planning. “Net-zero energy” has become a trendy phase, but is it truly feasible for large-scale pharmaceutical manufacturing facilities? As illustrated in Figure 1, construction spend on manufacturing facilities has nearly doubled in the United States since June 2021, according to the Department of the Treasury1. The two primary drivers of that surge domestically are semiconductors and pharmaceuticals. The US has an estimated 14.8 billion square feet (sq. ft.) of industrial and manufacturing space2, roughly 15.4% of the total square footage of commercial real estate. Furthermore, the total commercial square footage in the US is expected to grow to 124.6 billion by 20503, which, if the ratio of industrial square footage continues to hold, implies we will build 4.4 billion sq. ft. of new industrial and manufacturing space in the next 25 years. If those new manufacturing facilities use our current power grid with no significant changes or considerations for sustainable or on-site energy generation, we will have to plant a forest the size of the state of Vermont every year to offset carbon emissions for the new manufacturing buildings alone4, 5, 6, 7.

Constructing facilities to use net-zero energy is one solution to this issue. Net-zero energy usage, in the simplest terms, is creating a facility or campus that generates at least as much energy as it consumes. Although the concept can be great in theory, it becomes more difficult when you focus on manufacturing environments, as well as other sectors with high power usage densities.

This article features a case study examining the design of a fictional 200,000 sq. ft. manufacturing facility with a baseline energy use intensity of 150 kilo British thermal units (kBTU) per square foot per year. We are going to consider cost, space, geotechnical, and other considerations of pursuing net-zero usage for the facility, as well as energy savings, cost savings, and environmental impact of the decision throughout the first 15 years of operation.

NET-ZERO DESIGN CHALLENGES

Cost

The largest challenge for building a net-zero facility is cost. For manufacturing projects, you should assume that targeting net-zero energy usage is going to result in 15%–25% higher initial projects costs than a similar project not pursuing that goal. The additional cost comes from design and procurement of energy generation equipment. This includes solar panels or wind turbines, as well as upgrading building systems like heating, ventilation, and air conditioning (HVAC); plumbing; electrical; and even process equipment to higher efficiency models to minimize energy usage.

One of the most difficult cost-related obstacles to overcome is adapting your criteria for procurement to treat cost as secondary to efficiency, performance, and the environmental impact of the equipment. Because this shift in approach is nontraditional and requires organizational buy-in at every level of a team, communicating the approach and the goal for net zero early is key.

There are also several other avenues to consider that can help mitigate the higher project costs. First, involve site utility providers in the design process as early as possible and communicate the net-zero goal with them. Utility providers have a vested interest in making efficient projects, and they can often work with the design team to create custom grants for things like detailed energy modeling or covering the cost difference between a certain piece of building or process equipment and a more efficient model. Although this does add complexity and another stakeholder in the design process, it typically adds another valuable perspective to the table while helping reduce costs significantly.

Second, if the project and operational budget for the facility are structured such that initial project costs place net zero out of reach, but monthly energy cost is considered (which would be approximately zero if net zero was achieved), a project could choose to go into operation without the power generation equipment installed day one, and partner with an energy services company (ESCO) to install power generation equipment over the course of the first few years of operation.

This doesn’t necessarily save costs, but it does shift the cost from the capital project into the operational budget for the facility and splits up the cost over several years. Lastly, it could also be beneficial to engage an engineering and accounting firm to support the project. Although these hybrid firms are a rather recent addition to project landscapes, they can help identify tax credits and other government incentive programs that help put the project within reach.

Space

The next hurdle net-zero projects face, especially for high power density uses like manufacturing, is having the physical space for power-generating equipment. In the given example, the 200,000 sq. ft. building would need roughly 244,000 sq. ft. of solar panels to offset that energy usage, meaning the solar array couldn’t physically be housed on a traditional rooftop. Instead, this may require solar panel–covered entryways for the building, or to have a solar field elsewhere on the site for additional space. Obviously, having that many solar panels on the roof adds a significant structural load for the building as well, which can be another factor to consider that can add cost. If the project pursues wind turbines or a solar field, the space requirements should be considered, as well as how that will interface with parking and other logistical use requirements. It may impact the lot size needed for the project, even if the footprint of the building itself is already known.

Site Restrictions

One key method to save massive energy in new facilities is to use ground loop heating and cooling systems, both for HVAC and process loads, where applicable. However, not every project site is a good fit for these systems. Some sites have combinations of rock and soil types that would not be feasible to install a ground loop system in, and other sites might have soil compositions with poor thermal properties, where the full benefits of a ground loop system cannot be realized. Geotechnical testing and inspections on prospective project sites can confirm if the site will utilize a ground loop system effectively before moving forward with the land procurement and project delivery process.

Conviction and Accountability

As a net-zero project progresses, there will be a series of key decisions that could throw the sustainability goal off course. Perhaps an equipment vendor comes back with a significant lead time difference for a more efficient piece of equipment that may impact the project schedule, or the solar array size must get larger because the solar irradiance values for the project site are not as good as the team thought they would be. When these key decisions present themselves, it can be easy to revert to the traditional project management mindset and make decisions based on schedule and cost that jeopardize the net-zero goal. One effective method to combat this is to make the net-zero goal public once the organization and the project team agree on the direction. This adds a layer of environmental and societal accountability to the decision-making process.

NET-ZERO DESIGN BENEFITS

Energy Cost Savings

Once we navigate all the challenges, our example project will be set up to generate at least 8.8 million kilowatts (kW) of power every year. At the average US electricity rate9, we will save just shy of US $1.1 million in energy costs every calendar year. Over the course of the first 15 years of facility operation, this building would save about US $16.3 million in grid energy costs.

Any amount of equipment effciencies or on-site power generation goes a long way to reducing the environmental impact.

Environmental Impact

By designing this one building as net zero, we offset carbon emissions over the first 15 years of operation equivalent to planting a 700-acre forest. Every decision and every project where we prioritize net-zero thinking and have a bias for action works toward a more sustainable future.

Impact on Corporate Identity and Brand Trust

Over 70% of Americans say that sustainability is more important to them than ever before and it is a key consideration factor when selecting products or services10. Designing net-zero facilities works toward making climate action pledges and corporate goals into realities and builds trust with current employees and clients. Investing in a sustainable world-class facility can have a measurable return on investment in sales.

Energy Independence

Energy costs have continued to rise across the US and globally over the last decade, and in recent years has even approached 10%–15% increases year over year, surpassing typical market inflation and consumer cost index increases11. Rising energy costs and dependence on an aging energy grid are legitimate risks for businesses—especially in manufacturing, where process uptime is a critical success metric.

Conclusion

Designing and building net-zero manufacturing facilities may not always be possible; there are real challenges with initial cost and site limitations on space or geotechnical properties. However, as grid energy costs rise and sustainability contributes more to employment or product choices, the return on investment for pursuing net-zero facilities is going to become more attractive. Focusing on net-zero design can also set projects up to more easily pursue and achieve other key sustainability processes, like US Green Building Council LEED or the Living Building Challenge.

One other key shortcoming with how we think about net-zero design is that it is an all-or-nothing pursuit. This typically happens after the results of a feasibility study come in. If those results look like achieving net zero won’t be possible, it is easy to cast the idea and those design principles aside. Any amount of equipment efficiencies or on-site power generation we can add to projects goes a long way to reducing the environmental impact of the project and setting the stage for a more sustainable future. The following analogy comes to mind. If someone was considering becoming a runner and a feasibility analysis on “could I run a marathon?” came back negatively, the logical response wouldn’t be to not run at all. The better response would be to start making a training program, beginning with running as far as it is safe and productive to do so.

When we move past the challenges, there are also very substantive, intrinsic organizational and environmental benefits. Looking ahead to building 4.4 billion sq. ft. of new manufacturing space by 2050, it is our social responsibility to ask hard questions about what we can do to work toward net zero in those facilities. At the same time, we should ask how we can continue to adopt project delivery processes to place a larger focus on environmental impact.