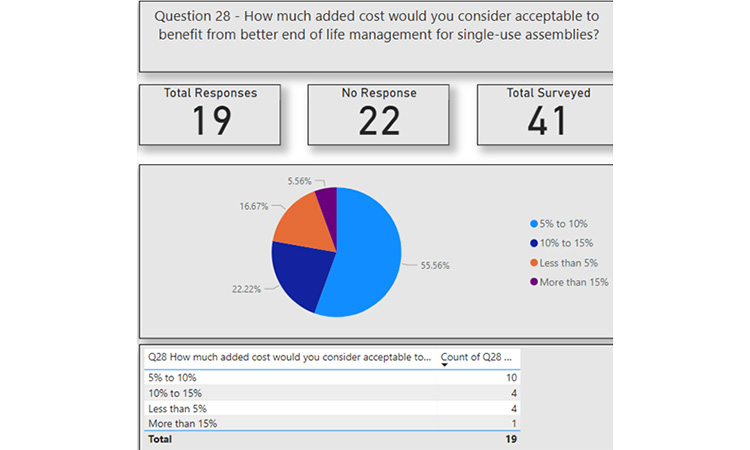

This shows that over half of the respondents would be willing to pay a small premium for the products they purchase for more sustainable disposal options. Purchasing cost sensitivities can impact the decision to choose a more sustainable product but looking more holistically at the total product life cycle cost may show a cost benefit if disposal impacts are reduced.

Survey participants were asked to rank various potential supplier offerings for better end-of-life management of single-use assemblies. The top 3 ranked options were:

- Have a third-party recycling company that can offer recycling and transport at the same or lower cost than current disposal method.

- Supplier optimizing packaging/reducing packaging waste.

- Additional cost for end-of-life management but with a more environmentally sustainable solution for disposal.

If suppliers improved the single-use assembly design for better end-of-life management, then most of the users would consider them for their processes.

85% percent of those responding would consider the improved designs for new and existing processes. Of which, 59% percent would consider replacing assemblies for existing processes. Respondents also indicated that their organizations would dedicate additional resources to supporting improved end-of-life management (81%). Typically, up to an added 10 hours a week (78%) is considered acceptable.

When asked for their suggestions of how suppliers can help in improving end-of-life management

15 people responded. The responses are grouped into the following categories with number of respondents shown in parenthesis.

- More information on options and approaches (4).

- Design the assemblies to be easily disassembled (4).

- Reduce the extent of single-use assemblies by using reusable systems (2).

- Suppliers take back used components/systems (2).

Other comments are aligned to approaches to recycling. For example, looking at greater use of thermoplastics for melting (1) and reuse through to chemical and biological approaches to recycling (2).

It is likely that the survey is self-selecting i.e. those that have a strong interest in this area have responded. However, it is encouraging that those that did respond are keen to actively take part in improving end-of-life management.

The survey respondents all have a strong commitment to recycling and actively supporting recycling efforts through the commitment of utilizing internal resources. Users are open to incorporating innovative designs for components/systems that ease end of life management.

Conclusions

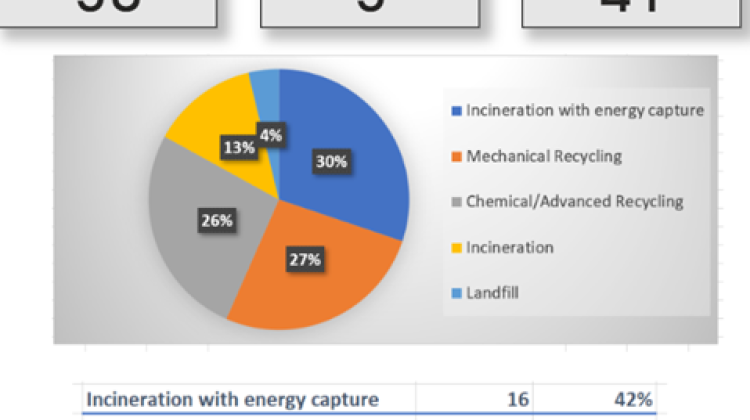

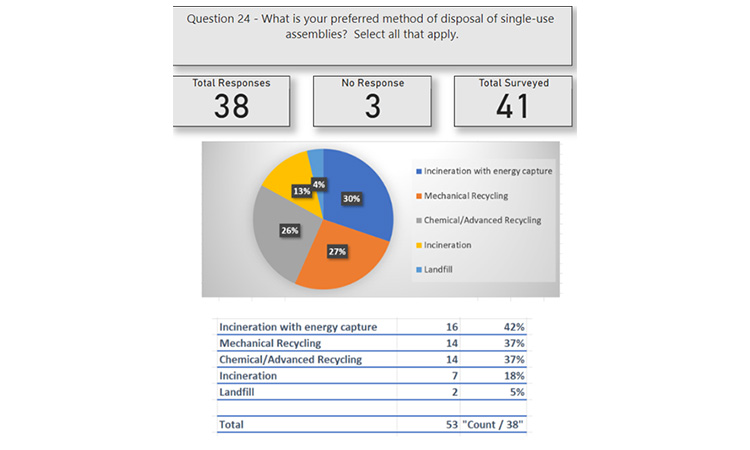

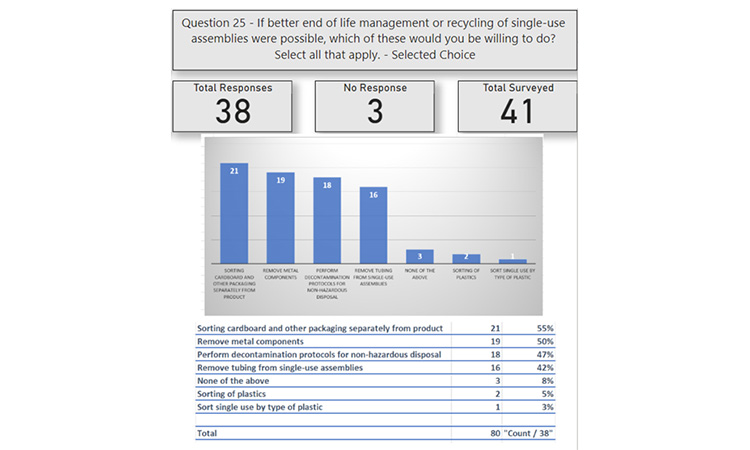

In Part 2 of this series, these survey results provide an insight into the users’ views on what they consider are the preferred disposal methods for single-use assemblies. Many users recognize that changing current practices would require different procedures and internal practices. Further, because the availability of alternatives today is limited, changes in current practices may require industry collaborations and leadership from one or more stakeholders.

Overall, the research summarized in this two-part series points to the following as likely viable options:

- For manufacturers: Design changes that facilitate disassembly at end-of-life or greater recyclability, optimize and reduce packaging waste, provide end-of-life solutions

- For end-users: Dedicate resource time to decontaminate and remove parts of the single-use assemblies to enable recycling

- For recyclers: Partner with suppliers to provide design recommendations for products that enable recycling and to conduct feasibility for recyclability of current designs

A common end user goal is to reduce the carbon emissions and environmental footprint associated with disposal of single-use solutions in the bioprocessing industry. There is a strong shared feeling that current waste methods are inadequate and can be improved; and this is borne out by the survey of users.

Direction is provided by the survey results. Of the options outlined there is a need to evaluate which of the above viable options offers the greatest potential for improvements for a given situation. In addition, looking outside at how other sectors tackle this issue would help inform our industry as we evaluate options.

By ISPE’s Disposables Community of Practice and the Sustainability Sub-Team

View Part 1: End-Of-Life Management for Single-Use Products in Bioproduction Part 1